roughing end mill depth of cut

The machining time spent roughing your workpiece is mostly determined by Material Removal Rate. Carbide can take more but staying with this guideline works for most of the end mills you will use.

7pcs 3 10mm 5 Flute Hss Countersink Drill Bit Set Carpentry Reamer Woodworking Chamfer End Milling Drill Bits Drill Bit Sets Drill

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

. From memory they are about 20mm 0800 and 10mm 38 with a plain spiral-fluted end mill - about 12mm 12 for scale. ANSI Catalog Number. Multi-flute end mills create better surface finishes due to a lighter chipload - per flute.

While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM. Cobalt roughing end mills are designed to withstand heat and abrasion and can be run at higher production rates without sacrificing tool life. Multi-Cut end mills are specifically designed for high-performance roughing operations.

This results in lower cutting pressures at a given radial depth of cut. Roughing end mill Short cut length 3 flute For aluminium alloy Corner radius roughing end mill Short cut length 3 flute For aluminium alloy. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

Pre-Hardened Steels Mold Steels Hardened Steels H13 D2 M3 4560 Hrc -. Now heres the last piece. 2000 L Overall Length.

Normally a 20 reduction in effective horsepower is used. Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Objective of rough pass is to remove bulk amount of excess material from.

Side loading is dramatically reduced with lower helix angles making it easier to mill thin walls. Vibration dampening variable flute spacing. Mm Aluminum alloy A7075 Cast aluminium AC4B.

Speeds and feeds charts for end mills from The Carbide End Mill Store. Every machining operation entails a radial and axial depth of cut strategy. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from.

Due to variable spacing of flutes combined with the NR roughing profile vibrations cutting forces are minimized and metal removal rates are maximized. Free easy returns on millions of items. Normally i would use a depth of cut of 31 to 625 with a 625 dia roughing end mill for a full width slot feeding straight across G1.

They are designed to remove large amounts of material quickly and more efficiently than standard end mills. Order Your Industrial Tools At Grizzly. Ad Browse discover thousands of brands.

Climb cut is recommended for side milling. Stabilizing cutting edge geometry. Standard depths of cuts for roughing end mills can be set at a larger value than ordinary type end mills.

Cutting speeds also vary with the end. 1016000 L Overall Length. Cobalt roughing end mills are designed.

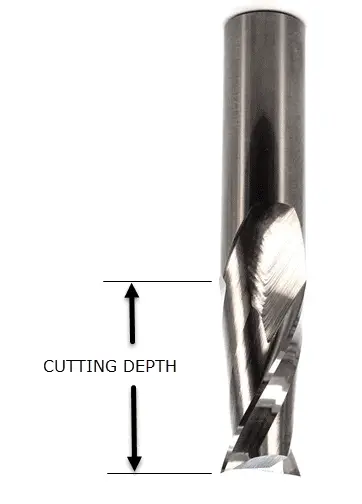

1st Maximum Cutting Depth. Shop categories METAL TOOLS - Reamer - Disc milling cutter - burrs - Drill - Shell end mills - cutter - Form cutter - Angle end mill - Graver - sinker - Plunge cutter - T-slot cutter - Radius cutter - end mill - face milling cutter - SK50 - NC center drill End mills with VHM cutting edges and tightening thread NEW diameter mm 20 shaft 25 total length mm 104 cutting length mm 33 to cut 4. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure.

Reduce your cutting forces by reducing speed andor feed or axial andor radial depth of cut. Free shipping on qualified orders. I am creating a new calculator based on your feedback.

45 high helix flute design. Now choose the right surface feet per minute SFM or surface meters per minute SMM. Depth of cut Revolution min-1 Feed rate mmmin Revolution min-1 Feed rate mmmin Dia.

Read customer reviews find best sellers. This means a 050-inch end mill will be engaged 0025 to 0050 inch. Roughers have chip-breaker cutting edges the peaks.

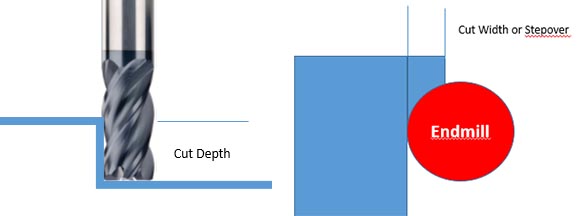

Shop Our Huge Selection of Fine Machinery. Order At Grizzly Now. Radial depth of cut RDOC the distance a tool is stepping over into a workpiece.

Change geometry - use an end mill with variable flute spacing or a small circular margin. Two flute end mills are center cutting where multi-flute end mills can vary. 508000 AP1MAX 1st Maximum Cutting Depth.

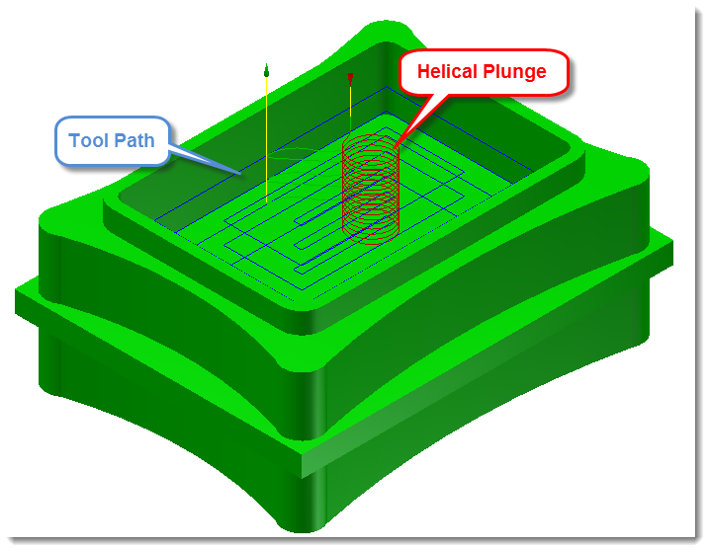

Machining to Zero with the Mold Meister Ball End Mill. CLF based on the radial depth of cut. Machining to appropriate depths whether slotting or peripheral milling profiling.

HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. High Performance Milling SFM750 RPM9500 Feed 80 ipm End Mill R4 Mold Steel 53HRC R4 Radial Depth 4mm axial Depth025. End mill was average length with 15 LOC flute for 58 dia end mill.

Increase your systems rigidity by changing over to a stub length end mill or improving your workpiece fixturing. The distance between scallops is referred to as pitch. ROUGHING END MILLS Roughing cuts are generally for preparing the surface.

Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project. Carbide Square End Mills. One Pass Grinding from Ball Nose to Outer Tooth.

Login Dear Customers Our supplier HTC is having substantial problems with supply chains due to Covid-19. Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use. Here are two of my roughers - aka Corncobs.

The tooth design and flute construction minimizes deflection and maximizes chip ejection. For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter. The deeper you go the slower you need to go.

For example the average recommended feed rate for a 050-inch tool is approximately 0002 inch per tooth. Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Volumes of material can be removed at high cutting speed.

Ad For Taps Dies Cutting and Measuring Tools. This setting will impact RCT calculations as well. This is because the cutting resistance is reduced because the chips are broken into short lengths by the wavy cutting edges.

They do cut very well - higher feed rates and depths and lengths of cuts - but over-loading or over-speeding will ruin them. I was wondering what others normally consider maximum depth of cut ratio to diameter of end mill with a roughing end mill milling cast iron medium hardness. HARVI III Aero Solid Carbide End Mill for High Feed Roughing and Finishing with Maximum Metal Removal Rates.

Also for the same reason the depth of cut for semi-finishing end mills can be increased. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. End Mill Speed Feed Calculator.

MRR Axial Depth of Cut Radial Depth of Cut Feed Rate all values in inches or inches per minute for Feed Rate This formula yields the number of cubic inches per minute your cutting tool is removing. This has to do with deflection of the end mill more than anything else. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

Ad Over 30 Years Of Quality Industrial Machinery Equipment. And Axial depth of cut ADOC the distance a tool engages a workpiece along its centerline are the backbones of machining. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material.

The Secret Mechanics Of High Feed End Mills In The Loupe

How To Make A Router Tenon Jig To Route Tenons With A Plunge Router This Is A Great Jig To Have In O Woodworking Techniques Diy Woodworking Woodworking Tools

Important Announcement Woodworking Wood Tools Diy Tools

How Deep Can I Cut On My Cnc Router Circle M Woodworking

More Bobcad Cam Roughing Pocketing Profiling Machining Operations

Optimize Depth Of Cut And Stepover For Better Cnc Milling

425 Carveco Maker Sign Making For Beginners Maker Beginners Signs

Selecting The Right Plastic Cutting End Mill In The Loupe

Need A Better Finish On Aluminum Check This Out Video Lyford Tool Company Cnc Programming

End Mill An Overview Sciencedirect Topics

What Is Depth Of Cut How Deep Can I Cut On A Single Pass Chris And Jim Cim